欢迎访问北京广宇大成数控机床有限公司的网站

欢迎访问北京广宇大成数控机床有限公司的网站

精密外圆磨床_磨床

φ200系列外圆磨床φ200SeriesCylindricalGrindingMachineToolM1320M1420MM1320MM1420MG1320MG1420机床性能结构特点Featuresofthemachinetoolperformanceandstructure砂轮架主轴采用大锥度套筒式高精度动压轴承主轴系,回转精度高,精度保持时间长。回转精度≤0.001mm。Spindleofthewheelheadusesthedynamicpressurebearingspindleofbig-taperedtelescope-feedandhigh-precision,whichhasthehighrotationprecisionandlongtimemaintenance.Therotationprecisionis≤0.001mm.砂轮进给机构采用齿轮结构,操作灵活准确。最小进给量为0.001mm。Grindingwheelfeedmechanismusesgearstructure,whichisflexibleandaccuratetooperate.Minimumfeedamountis0.001mm.头架旋转采用交流变频无极调速,调速灵活方便。HeadstockrotationcontrolledbysteplessACfrequencyconversion,itisflexibletoregulatethespeed.万能型机床头架回转主轴采用高精度进口滚动轴承。从高速到低速均可保持高精度、高刚性运转。主轴回转精度≤0.001mm。Therotaryspindleoftheuniversaltypemachine’sheadstockusesimportedhigh-precisionrollingbearings.Fromhighspeedtolowspeed,thehigh-precisionandhigh-rigidityoperationcanbemaintained.Spindlerotationprecisionis≤0.001mm.工作台为双层结构,最大锥度调整可达9°。Theworkbenchisdouble-deckstructure;themaximumtaperadjustmentcanbeupto9°.机床加工精度高,整体布局合理,造型美观,操作手柄集中、形象、操作简便、安全。Withhighmachiningprecision,theintegrallayoutofmachinetoolisrational,appearanceisattractive,operatinghandlesarecentralizedarrangeandvisualization,thustomakethemachineeasytocontrolandsafetooperate.进给导轨使用贴塑导轨,提高了慢速运行平稳性及抗振性。Thefeedingguidewayusesantifrictionplastic-filmingguideway,thuspromotingthesmoothnessandvibrationresistanceoflow-speedoperations..机床液压驱动采用螺杆泵,运行平稳,噪音低。Thehydraulicdrivesystemusesscrewpumpwhichisofsmoothrunningandlownoise.

数控外圆磨床_外圆磨床

200/320系列数控外圆磨床是一种高效率、高精度型数控外圆磨床,包括外圆磨床、端面外圆磨床。200系列最大加工直径200mm,加工长度为500mm、750mm两种规格。320系列最大加工直径320mm,加工长度为750mm、1000mm、1500mm三种规格。适用各种多轴颈圆柱类大批量零件的外圆、轴肩、锥面的高效磨削。该数控外圆磨床为两轴联动数字控制。机床具有工件自动轴向定位、砂轮自动切入、工作台自动跳档、加工工件尺寸的自动测量、两轴联动自动修整砂轮和修整后的自动补偿、砂轮恒线速磨削等功能。配装原装进口数控系统。200/320SeriesCNCcylindricalgrindingmachineisthekindofCNCcylindricalgrindingwithhigh-efficiencyandhigh-precision,includingcylindricalgrinding,andendfacecylindricalgrinding.200Seriesmaximummachiningdiameteris200mm,andtheprocessinglengthcontains500mmand750mmtwospecifications.320Seriesmaximummachiningdiameteris320mm,andtheprocessinglengthcontains750mm,1000mmand1500mmthreespecifications.Itisapplicabletothehighefficiencygrindingofmasscylinders’excircles,shaftshoulders,andconesofmultijournals.TheCNCcylindricalgrindingiscontrolledbytwoaxisdigitalcontrolsystem.Themachineownsthefunctionslikeautomaticaxialpositioning,grindingwheelautomaticallycut-in,workbenchautomaticallyjump,automaticsizemeasurement,two-axisautomaticdressingofthegrindingwheelandautomaticallycompensateforgrindingwheelafterthemodification,wheelgrindingwithconstantlinearvelocity,andsoon.ThemachineequippedwithimportedoriginalCNCsystem.

YGK系列数控端齿磨床_数控端齿磨床

YGK78系列机床采用西门子数控系统及交流伺服驱动,四轴控制两轴联动。机床采用立式部局,滑板在栋梁上横向移动(X轴),两个立磨头可分别在滑板上做上、下进给运动(Z1、Z2轴)。三个直线坐标轴均装有海德汉光栅尺作为全闭环反馈。床身上装有高精度数控回转工作台可实现工件的分度定位。转台内装有海德汉圆光栅作为全闭环反馈。转台的左侧安装金刚石碟片修整器,X轴可分别同Z1或Z2轴实现两轴联动,通过插补运动对砂轮进行齿形修整,加工时对工件进行成型切入磨削。左、右两个立磨头可分别加工凸齿、凹齿、倒角等工序。YGK78seriesmachinetoolshasbeenverticallayout.Twogrindingspindlesindependentlymoveupordown(Z1Z2axes)onthecarriage,whichcouldmakehorizontalmovementonthecrossbeam(Xaxes).Threelineaxes(Z1,Z2andX)equippedwithHeidenhaingratingscales,carryoutclose-loopcontrol.Therehastwogrindingspindles,soastogrindingconvexandconcaveteeth(onthecoupling),respectively.Theworkpieceissetuponaprecisionrotarytable,whichissupportedonahydrodynamic-staticpressurebearing,directlydriven,andequippedwithHeidenhainencoder,forprecisionindexing.机床配有我公司针对弧齿磨削工艺而开发的专用软件,可实现参数化编程。机床配备两套程序:齿形设计程序和加工程序。用户可根据自己现有的齿形参数和工艺参数通过图形化界面输入数控系统,实现对工件的加工。Thegrindingmachinehasaccompaniedwithaspecialsoftware,consistofdesignprogramandprocessprogram.Theformermakesuseofverifyorcorrectaworkpiecedesign;andthelattermakesgooduseofparameterandgraph,towritprocessprogram,theninputtomachine’sCNCsystem,toaccomplishtheprocessoftheworkplece.YGK系列机床是我公司新产品,已被列为北京市科委2012年的科研课题,课题号为D121100002612001。YGK78系列机床专门用于端面弧齿磨削加工。YGK78seriesmachinetoolsisanewproductforourcompany.Andit’saresearchprojectforBeijingscienceandtechnologycommittee,in2012,theprojectnumberisD121100002612001.YGK78seriesmachinetoolsisaspecializedgrinder,forgrindingthecomvexandconcaveteethofendcoupling.

五轴联动数控加工中心_加工中心

VCM系列五轴联动数控加工中心是我公司自主研发的一款新产品,通过五轴联动工件可以在一次装夹后自动连续完成多个空间曲面的高速加工。主要适用于叶轮、叶片等具有复杂曲面的零件以及型腔模、压铸模、冲压模等各类模具的加工制造,还有阀体、薄壁类、壳体类框架类零件的柔性高效加工。该机床功能部件精度、性能指标处于国内先进水平,具有转速高、联动结构稳定、五轴联动技术成熟的特点。机床主要配置:三面闭式静压导轨(自有专利技术)摇篮式复合转台(自有专利技术)大功率直驱力矩电机高精度电主轴高精度角度编码器摇篮式复合转台摇篮式复合转台是我公司独立研发的具有自主知识产权和专利技术的动静压复合转台。该结构转台具有高分度精度、高刚度和长寿命等优点。

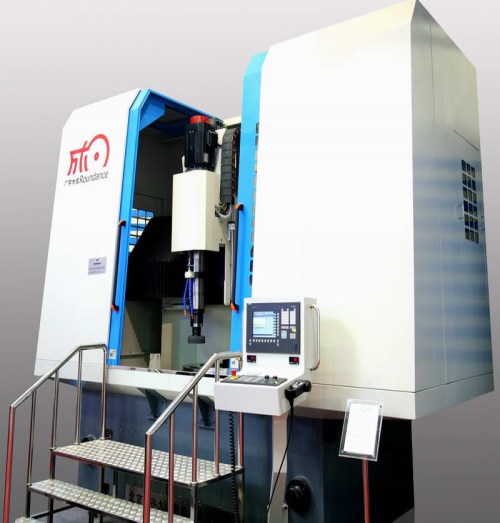

高精度数控立式磨床_立式磨床

MGK28是我公司自行设计研制的高精度、高刚性、全闭环数字化控制的立式复合磨床系列。该系列磨床采用了我公司专利技术(ZL201200036107.8),结构设计合理、紧凑;工件可一次装夹后完成对内孔、外圆和台阶面的多工序磨削加工,确保零件对位置精度的更高要求;该系列磨床驱动系统具有良好的动态品质,执行元件精度高、可靠性好、响应速度快、具备国际同等先进技术水平;广泛应用于轴承、风电、工程机械、阀门、汽车、军工、机器人等重要国民经济领域。MGK28seriesmachinetoolsareaseriesofverticalcompositegrinderswithhighprecisionandrigidity,andfullclosed-loopdigitalcontrol,whichareindependentlydesignedanddevelopedbyGuangyudacheng.Thisseriesofgrindersadoptthepatentedtechnology(ZL201200036107.8)developedbyGuangyudacheng,withreasonabledesignandcompactstructure;whileaworkpieceisputonatable,multi-proceduregrindingcanbeperformedfortheinternalhole,outercircleandsteporendfaceinonelocatingtoensuretoachievemuchaccuracyoftheworkpiece.Thedrivingsystemsofthegrindershavegooddynamicresponsecharacteristicsandtheactuatingelementshavehighprecision,goodreliabilityandhighresponsespeed.Theadvancedtechnicallevelofthemachineshavereachedtheinternationaladvancedlevels.Themachinesarewidelyappliedtosuchimportantnationaleconomyfieldsasbearing,windpowerequipment,engineeringmachinery,valves,automobiles,militaryandrobotindustry,etc.

Copyright © 北京广宇大成数控机床有限公司