- 您当前的位置:

- 首页>

- 产品中心 >精密外圆磨床 >精密外圆磨床报价_数控外圆磨床

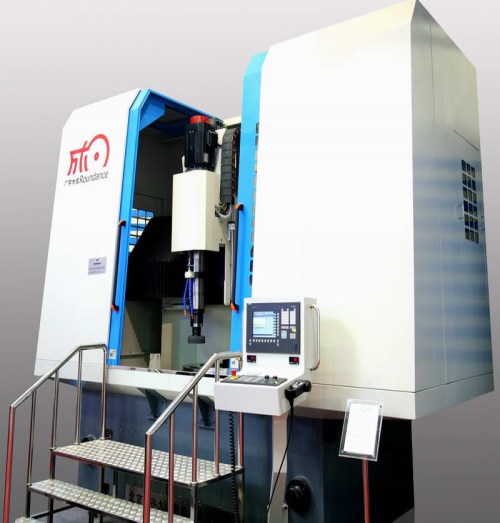

φ200 系列外圆磨床

φ200 Series Cylindrical Grinding Machine Tool

M1320 M1420

MM1320 MM1420

MG1320 MG1420

机床性能结构特点 Features of the machine tool performance and structure砂轮架主轴采用大锥度套筒式高精度动压轴承主轴系,回转精度高,精度保持时间长。回转精度≤0.001mm。

Spindle of the wheel head uses the dynamic pressure bearing spindle of big-tapered telescope-feed and high-precision, which has the high rotation

precision and long time maintenance.The rotation precision is ≤0.001mm.

砂轮进给机构采用齿轮结构,操作灵活准确。最小进给量为0.001mm。

Grinding wheel feed mechanism uses gear structure, which is flexible and accurate to operate. Minimum feed amount is 0.001mm.

头架旋转采用交流变频无极调速,调速灵活方便。

Headstock rotation controlled by stepless AC frequency conversion, it is flexible to regulate the speed.

万能型机床头架回转主轴采用高精度进口滚动轴承。从高速到低速均可保持高精度、高刚性运转。主轴回转精度≤0.001mm。

The rotary spindle of the universal type machine’s headstock uses imported high-precision rolling bearings. From high speed to low speed, the

high-precision and high-rigidity operation can be maintained. Spindle rotation precision is ≤0.001mm.

工作台为双层结构,最大锥度调整可达9 °。

The workbench is double-deck structure; the maximum taper adjustment can be up to 9 °.

机床加工精度高,整体布局合理,造型美观,操作手柄集中、形象、操作简便、安全。

With high machining precision,theintegral layout of machine tool is rational, appearance is attractive, operating handles are centralized arrange

and visualization, thus to make the machine easy to control and safe to operate.

进给导轨使用贴塑导轨,精密外圆磨床报价,高精密外圆磨床,提高了慢速运行平稳性及抗振性。

The feeding guideway uses antifriction & plastic-filming guideway,thus promoting the smoothness and vibration resistance of low-speed operations..

机床液压驱动采用螺杆泵,运行平稳,噪音低。

The hydraulic drive system uses screw pump which is of smooth running and low noise.

φ320 系列外圆磨床

φ320 Series Cylindrical Grinding Machine Tool

M1332 M1432

MM1332 MM1432

MG1332 MG1432

¾ 机床性能结构特点 Features of the machine tool performance and structure

砂轮架主轴采用大锥度套筒式高精度动压轴承主轴系,回转精度高,精度保持时间长。回转精度≤0.001mm。

Spindle of the wheel head uses the dynamic pressure bearing spindle of big-tapered telescope-feed and high-precision, which has the high rotation

precision and long time maintenance.The rotation precision is ≤0.001mm.

砂轮进给机构采用齿轮结构,操作灵活准确。最小进给量为0.001mm。

Grinding wheel feed mechanism uses gear structure, which is flexible and accurate to operate. Minimum feed amount is 0.001mm.

头架旋转采用交流变频无极调速,调速灵活方便。

Headstock rotation controlled by stepless AC frequency conversion, it is flexible to regulate the speed.

万能型机床头架回转主轴采用高精度进口滚动轴承。从高速到低速均可保持高精度、高刚性运转。主轴回转精度≤0.001mm。

The rotary spindle of the universal type machine’s headstock uses imported high-precision rolling bearings. From high speed to low speed, the

high-precision and high-rigidity operation can be maintained. Spindle rotation precision is ≤0.001mm.

工作台为双层结构,最大锥度调整可达9 °。

The workbench is double-deck structure; the maximum taper adjustment can be up to 9 °.

机床加工精度高,整体布局合理,造型美观,操作手柄集中、形象、操作简便、安全。

With high machining precision,theintegral layout of machine tool is rational, appearance is attractive, operating handles are centralized arrange

and visualization, thus to make the machine easy to control and safe to operate.

进给导轨使用贴塑导轨,提高了慢速运行平稳性及抗振性。

The feeding guideway uses antifriction & plastic-filming guideway,thus promoting the smoothness and vibration resistance of low-speed operations..

机床液压驱动采用螺杆泵,运行平稳,噪音低。

The hydraulic drive system uses screw pump which is of smooth running and low noise.

国内现有水平:上海原创精密机床主轴有限公司研制的液体(动)静压电主轴,额定功率和最高转速达到34kW、8500r/min,径向跳动1μm。东方精益公司生产的液体(动)静压电主轴,额定功率/最高转速达到17kW、8000r/min,径向跳动1μm,精密外圆磨床报价,径向刚度>500N·μm。湖南大学针对超高速外圆/凸轮轴磨床开发了电动机内置式液体(动)静压电主轴,额定功率和最高转速达35kW、10000r/min,北京广宇大成数控机床有限公司,广宇大成数控机床,径向圆跳动1μm;同时还针对高速内圆磨床,开发了12kW、30000r/min电动机内装式液体动静压电主轴。北京航空航天大学下属的北京北航精密有限公司开发了系列(动)静压主轴产品,精密外圆磨床报价,大型外圆磨床价格,额定功率和最高转速达到7.5kW、48000r/min,回转精度能达到0.5μm以内。在内圆磨(动)静压主轴方面,国内已生产转速达20000r/min,主轴直径28mm的主轴产品。目前国内液体(动)静压主轴的回转精度最高能达到0.1μm。φ500/φ630/φ800 系列大型外圆磨床

φ500/φ630/φ800Series Large Cylindrical Grinding Machine Tool

M1350 M1450

M1363 M1463

M1380

¾ 机床性能结构特点 Features of the machine tool performance and structure

砂轮架主轴采用高刚性套筒式动静压轴承轴系,回转精度高,精度保持时间长。

Spindle of the wheel head uses the by high rigidity sleeve type hydrostatic/hydrodynamic bearing, which has the high rotation precision and long

time maintenance.

砂轮进给机构采用齿轮结构,操作灵活准确。最小进给量为0.0025mm。

Grinding wheel feed mechanism uses gear structure, which is flexible and accurate to operate. Minimum feed amount is 0.0025mm.

头架旋转采用交流变频无极调速,调速灵活方便。

Headstock rotation controlled by stepless AC frequency conversion, it is flexible to regulate the speed.

万能型机床头架回转主轴采用高精度进口滚动轴承。从高速到低速均可保持高精度、高刚性运转。主轴回转精度≤0.003mm。

The rotary spindle of the universal type machine’s headstock uses imported high-precision rolling bearings. From high speed to low speed, the

high-precision and high-rigidity operation can be maintained. Spindle rotation precision is ≤0.003mm.

工作台为双层结构,最大锥度调整可达5 °。

The workbench is double-deck structure; the maximum taper adjustment can be up to 5°.

机床加工精度高,整体布局合理,造型美观,操作手柄集中、形象、操作简便、安全。

With high machining precision,theintegral layout of machine tool is rational, appearance is attractive, operating handles are centralized arrange

and visualization, thus to make the machine easy to control and safe to operate.

进给导轨使用贴塑导轨,提高了慢速运行平稳性及抗振性。

The feeding guideway uses antifriction & plastic-filming guideway,thus promoting the smoothness and vibration resistance of low-speed operations..

机床产业重点抓好制造水平升级、产品可靠性升级、机床外观升级,提高产品档次和品质,全面推进高精、高速、高效发展战略,在产品品质和规模化生产上要有所作为;要继续以客户为中心,努力满足用户对产品的个性化需求,为其提供完善的工艺技术解决方案;重点抓好与西工大合作项目及重要客户战略性合作产品的生产制造和销售服务工作;对丝杠、导轨厂现有加工设备逐台进行高精、高效升级改进;对SK74系列数控丝杠磨床、SK76系列数控内螺纹磨床、简易数控曲轴磨床等重点新产品进行完善改进。 根据航空工业加工件的结构特点和加工要求,需要带A、B摆角或A、C摆角的五轴联动加工中心、高速加工中心、大型双龙门立式加工中心、大型数控龙门镗铣床、精密数控车床、大型数控精密立式车削中心、车铣复合加工中心、叶盘高效加工中心、端面弧齿磨床、高速转子叶尖磨床、缓进给强力磨床、拉床、相关电加工机床、激光熔覆加工机床、板类件无模多点成形压力机、定向单晶熔炼炉、电液束流设备等。要求机床具有足够的刚性,操作简单,人机界面清楚,要求样条插补(NURBS),过程均匀控制,以减少对拐角处加工精度的影响,具有在线测量仿真功能。

欢迎访问北京广宇大成数控机床有限公司的网站

欢迎访问北京广宇大成数控机床有限公司的网站